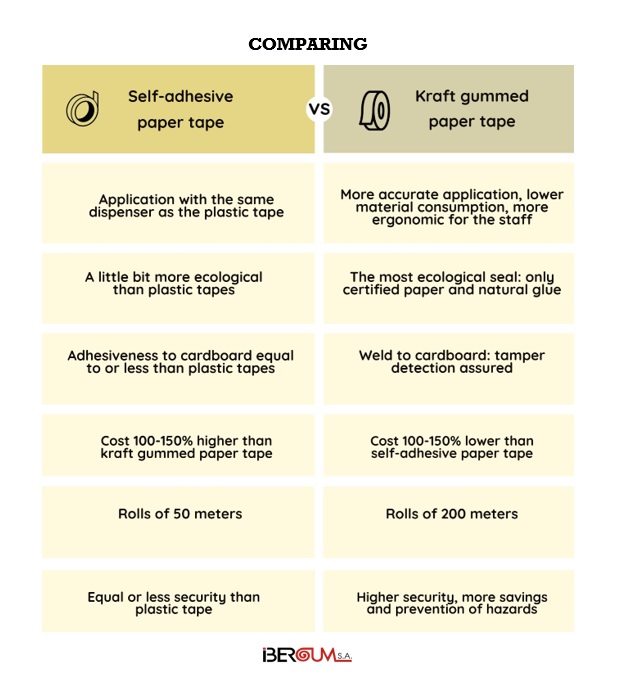

Some of our new clients, before making the decision about the change to kraft gummed paper tape for the sealing of their cardboard boxes, ask us about self-adhesive tape they have heard of or seen on occasions. They consult us regarding the existing differences between it and kraft gummed paper tape, and the advantages and disadvantages that both offer.

Self-adhesive paper tape and kraft gummed paper tape: similar, but very different

At first glance, self-adhesive paper tape looks very similar to Kraft gummed paper tape, since both are made of kraft paper and are therefore similar in color and texture. However, they are very different and, both in their form of application and their technical characteristics and results, they show great differences in their respective levels of effectiveness.

Advantages and disadvantages of self-adhesive paper tape

Advantages

- Its application is done with the same dispenser as the adhesive plastic tape.

- It is a somewhat more ecological alternative to plastic adhesive tapes, but not the best in environmental terms.

Disadvantages

- Adhesiveness to cardboard is equal to or less than plastic adhesive tape.

- Its cost is 100-150% higher than that of water activated tape.

- The standard length of the roll is 50 meters.

- Offers the same, or even less, shipping security than plastic tape.

Advantages of kraft gummed paper tape versus self-adhesive paper tape

- Gummed paper tape is the most ecological and sustainable seal: its composition based on Kraft paper from sustainable crops, and glue from potato starch, make it recyclable without separation from the cardboard box, and biodegradable.

- Gummed paper tape welds with the cardboard: in case of undesired manipulation of the cardboard box, it is detected immediately.

- The standard length of the Kraft gummed paper tape roll ss 200 meters. Less changes and more efficiency.

- Gummed paper tape achieves less material consumption for the closure of the cardboard box. With a single strip closing de upper flaps and another strip for the lower ones, the cardboard box is perfectly sealed.

- The cost of kraft gummed paper tape is 100-150% lower than self-adhesive paper tape, which, added to the lower consumption of material, means great savings in packaging cost.

- Its application is considerably less aggressive for the operators joints in the packaging areas than the application with a dispenser of any adhesive or self-adhesive tape. The gummed paper tape is applied with desktop machines that increase the ergonomics of the operating personnel and prevent occupational hazards, while optimizing material measurements and times, improving productivity.

Consequently, the kraft gummed paper tape, in comparative analysis with the self-adhesive paper tape, is safer, more economical, more ecological, and healthier.

Comparative answers help companies to choose the most appropriate solutions for their needs and expectations in terms of saving costs and production.